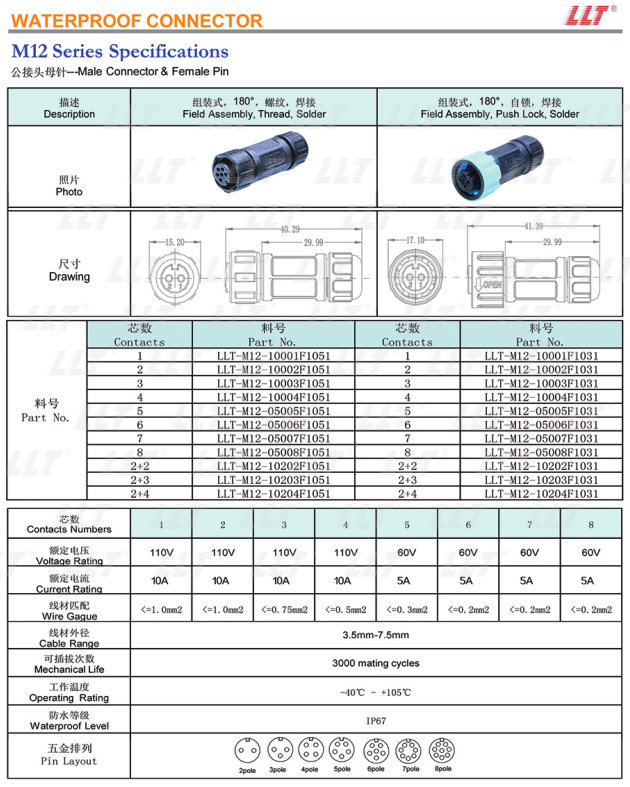

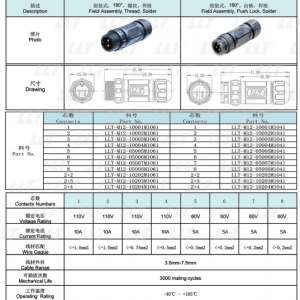

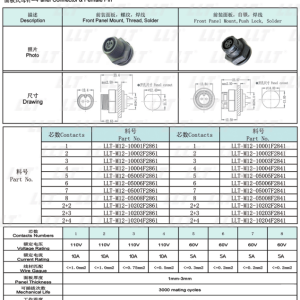

LLT M12 Push Lock Connector Series

Certified Quality

LLT M12 Push Lock Connector Core Technology

Advanced Push Lock Technology

Features patented spring-loaded push lock design with IP68 waterproof rating. The locking mechanism provides audible click confirmation ensuring secure connection. Compatible with leading grow lighting systems including Signify, Philips Lighting, and uPowerTek full spectrum grow lights.

Versatile Installation Options

Available in pre-wired cable assemblies and threaded panel mount configurations. Proven performance in landscape lighting applications for over 10 years, including partnerships with Powerland and other leading outdoor lighting manufacturers.

Connection Types Comparison

Standard Threaded

Industrial standard for all environments.

- Secure MountVibration resistant, stable connection.

- Cost EffectiveEconomical for volume production.

- Wide ApplicationAutomation/robotics/sensors.

LLT™ Patented Push Lock Recommended

Advanced design for enhanced efficiency and reliability.

- Quick ConnectTool-free, one-touch connection, time-saving.

- Clear Feedback"Click" audible confirmation.

- 90% Faster InstallationSignificantly reduces installation and maintenance costs.

Bayonet Lock

Balanced efficiency and cost solution.

- Quick LockEasy operation, secure retention.

- WaterproofSuitable for wet/outdoor environments.

- Global MarketPopular in international markets.

LLT Connector · Landscape Lighting Applications

Application Areas

About LLT Connector Shen zhen

Shenzhen LLT Connector Co., Ltd.

Plant(Dongguan): 150,000m²

200+ patents

Leading Electrical Connection Solutions Provider

As a National High-Tech Enterprise (2023), LLT Connector provides world-class electrical connection solutions through comprehensive R&D capabilities, 200+ technical patents, and vertically integrated manufacturing. Our products serve landscape lighting (with 50%+ market share in grow lighting connectors), solar energy, and industrial automation applications worldwide.

Custom solutions for EV high-voltage platforms (400V/800V) and fast charging waterproof connections.

Advanced Manufacturing Facilities

OEM/ODM Customization Service Process for Wire & Cable Connectors

Requirements Analysis & Wire Connector Design

Our experienced engineering team evaluates customer specifications, drawings, and technical requirements to create preliminary wire connector designs and cable assembly solutions.

OEM Tooling Agreement & Technical Development

Upon signing the OEM tooling development agreement and initial payment (typically 30%), our engineers begin detailed technical drawings for custom connector tooling and manufacturing processes.

Prototype Manufacturing & Sample Validation

Following design approval, we proceed with precision tooling fabrication and provide prototype connector samples for comprehensive customer validation and testing.

Pre-Production Documentation Review

Before mass production of wire connectors and cable assemblies, customers conduct final review of production documentation, technical specifications, and quality standards with full engineering support.

Custom Packaging & Branding Solutions

We offer standard packaging options and custom OEM/ODM packaging solutions tailored to customer requirements, ensuring product protection and brand identity consistencyfor connector manufacturers.

Value-Added Manufacturing Services

Specialized services include cable termination, custom labeling, contract manufacturing, and precision injection molding for complete wire equipment and lighting connector solutions.

CLICK TO EMAIL – BULK ORDER DISCOUNTS!

CLICK TO EMAIL – BULK ORDER DISCOUNTS! Click above to send email for bulk pricing negotiation

Click above to send email for bulk pricing negotiation

Live Chat (Office Hours: 8AM-10PM GMT+8)

Live Chat (Office Hours: 8AM-10PM GMT+8)

Reviews

There are no reviews yet.